Durable Bending 302 Stainless Steel Round Bar 4mm JIS Duplex For Long Lasting

| Place of Origin | China |

|---|---|

| Brand Name | Tisco |

| Certification | ISO/ TUV/ SGS /BV and so on |

| Model Number | Stainless Steel Bar |

| Minimum Order Quantity | 1 Ton |

| Price | Negotiated |

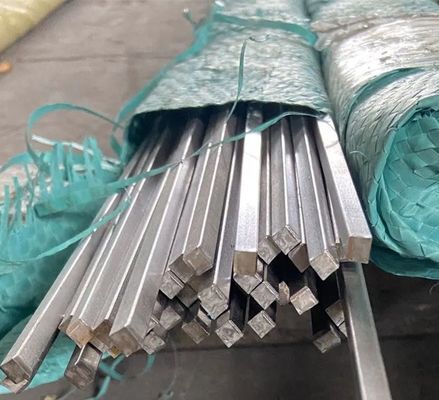

| Packaging Details | Export standard package: bundled wooden box or bag(According to customer's requirement) |

| Delivery Time | 7-15 Work Days |

| Payment Terms | L/C, T/T |

| Supply Ability | 10000 Ton/Tons per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

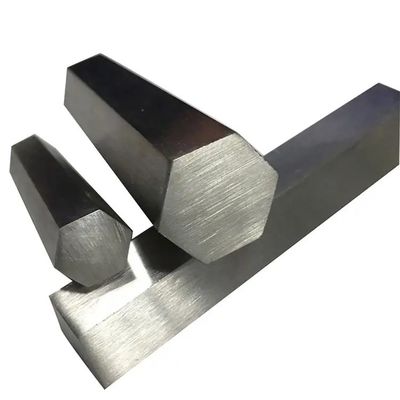

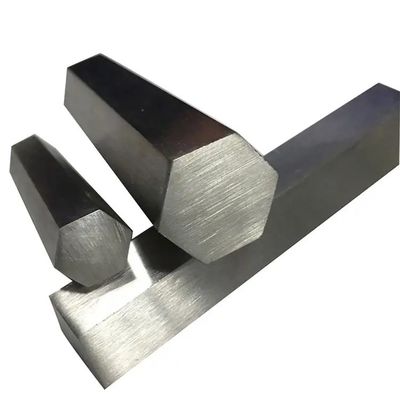

x| Name | Stainless Steel Bar | Shape | Round/Flat/Square |

|---|---|---|---|

| Material | 201/304/304L/321/316/316L/310S/309S/316Ti | Application | Construction Building Industry |

| Special Use | Valve Steels | Processing Service | Bending, Welding, Decoiling, Punching, Cutting |

| Keyword | Stainless Steel Bar Rod | Technique | Forging And Cold Drawing |

| Edge | Mill Edge Slit Edge | ||

| Highlight | 4mm 302 Stainless Steel Round Bar,Bending 302 Stainless Steel Round Bar,JIS Duplex Stainless Steel Bar |

||

Durable Stainless Steel Bar For Long-Lasting Performance

Applications

Industrial Manufacturing: Stainless steel rods are used extensively in industrial manufacturing applications to produce components such as shafts, valves, fasteners, and fittings.

Construction: Stainless steel rods are used in construction applications such as reinforcement bars in concrete, railing, and handrails due to their high strength and corrosion resistance.

Automotive: Stainless steel rods are used in automotive applications such as exhaust systems and suspension parts due to their high strength and resistance to corrosion and heat.

Aerospace: Stainless steel rods are used in aerospace applications such as aircraft engine components due to their high strength-to-weight ratio and resistance to high temperatures and corrosion.

Marine: Stainless steel rods are used in marine applications such as boat fittings and marine hardware due to their high resistance to corrosion and rust.

Medical: Stainless steel rods are used in medical applications such as surgical instruments, orthopedic implants, and dental implants due to their biocompatibility, corrosion resistance, and strength.

Food Processing: Stainless steel rods are used in food processing applications such as conveyor systems, tanks, and equipment due to their corrosion resistance and hygienic properties.

| Type: | Stainless Steel Bar |

| Outer Diameter: | 4-600mm (3/8"-25") |

| Length: | 40-400mm,2000mm, 2500mm, 3000mm, 5800mm, 6000mm,12000mm, etc |

| Standard: | ASTM,JIS, AISI, GB, DIN, EN |

| Surface: | BA,2B,NO.1,NO.4,4K,HL,8K |

| Application: | It is widely used in high-temperature and electric industry, medical devices, construction, chemistry, food industry, agriculture, and ship components.It also applies to food and beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen mesh etc. |

| Certification: | ISO, SGS,BV |

| Technique: | Forging and cold drawing |

| Edge: | Mill Edge Slit Edge |

| Quality: | SGS Inspection |

| Grade (ASTM UNS) | 201,304,304L,321,316,316L,317L,347H,309S,310S,904L ,S32205,2507,254SMOS,32760,253MA,N08926 |

| Grade (EN) | 1.4301,1.4307,1.4541,1.4401,1.4404,1.4571,1.4438,1.4539,1.4547, 1.4529,1.4562,1.4410,1.4878,1.4845,1.4828,1.4876,2.4858,2.4819 |

| Package | Standard sea-worthy package or as required |

| Supply ability | 10000 tons/month |

| MOQ | 1Ton |

| Processing Service | Bending, Welding, Decoiling, Punching, Cutting |

Chemical Component

|

Grade

|

C

|

Si

|

Mn

|

P

|

S

|

Ni

|

Cr

|

Mo

|

|

201

|

≤0.15

|

≤0.75

|

5.5-7.5

|

≤0.06

|

≤0.03

|

3.5-5.5

|

16.0-18.0

|

-

|

|

202

|

≤0.15

|

≤1.0

|

7.5-10.0

|

≤0.06

|

≤0.03

|

4.-6.0

|

17.0-19.0

|

-

|

|

301

|

≤0.15

|

≤1.0

|

≤2.0

|

≤0.045

|

≤0.03

|

6.0-8.0

|

16.0-18.0

|

-

|

|

302

|

≤0.15

|

≤1.0

|

≤2.0

|

≤0.035

|

≤0.03 |

8.0-10.0

|

17.0-19.0

|

-

|

|

304

|

≤0.08

|

≤1.0

|

≤2.0

|

≤0.045

|

≤0.03

|

8.0-10.5

|

18.0-20.0

|

|

|

304L

|

≤0.03

|

≤1.0

|

≤2.0

|

≤0.035

|

≤0.03

|

9.0-13.0

|

18.0-20.0

|

|

|

309S

|

≤0.08

|

≤1.0

|

≤2.0

|

≤0.045

|

≤0.03

|

12.0-15.0

|

22.0-24.0

|

|

|

310S

|

≤0.08

|

≤1.5

|

≤2.0

|

≤0.035

|

≤0.03

|

19.0-22.0

|

24.0-26.0

|

|

|

316

|

≤0.08

|

≤1.0

|

≤2.0

|

≤0.045

|

≤0.03

|

10.0-14.0

|

16.0-18.0

|

2.0-3.0

|

|

316L

|

≤0.03

|

≤1.0

|

≤2.0

|

≤0.045

|

≤0.03

|

12.0-15.0

|

16.0-18.0

|

2.0-3.0

|

|

321

|

≤0.08

|

≤1.0

|

≤2.0

|

≤0.035

|

≤0.03

|

9.0-13.0

|

17.0-19.0

|

-

|

|

904L

|

≤2.0

|

≤0.045

|

≤1.0

|

≤0.035

|

-

|

23.0-28.0

|

19.0-23.0

|

4.0-5.0

|

|

2205

|

≤0.03

|

≤1.0

|

≤2.0

|

≤0.030

|

≤0.02

|

4.5-6.5

|

22.0-23.0

|

3.0-3.5

|

|

2507

|

≤0.03

|

≤0.80

|

≤1.2

|

≤0.035

|

≤0.02

|

6.0-8.0

|

24.0-26.0

|

3.0-5.0

|

|

2520

|

≤0.08

|

≤1.5

|

≤2.0

|

≤0.045

|

≤0.03

|

0.19-0.22

|

0.24-0.26

|

-

|

|

410

|

≤0.15

|

≤1.0

|

≤1.0

|

≤0.035

|

≤0.03

|

-

|

11.5-13.5

|

-

|

|

430

|

0.12

|

≤0.75

|

≤1.0

|

≤0.040

|

≤0.03

|

≤0.60

|

16.0-18.0

|

-

|

![]()

![]()

![]()

Application

![]()

Delivery

![]()

![]()

FAQ