8k Heat Resistant Stainless Steel Sheet 0.3mm Brushed Hot Rolled Rustproof

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Stainless Steel Sheet | Type | Cold / Hot Rolled |

|---|---|---|---|

| Machining | Turning / Milling / Planing / Drilling / Boring / Grinding / Gear Cutting / CNC Machining | Deformation Processing | Bending / Cutting / Rolling / Stamping |

| Tolerance | ±1% | Surface | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

| Keyword | Stainless Steel Plate | Special Request | Can Be Customized |

| Color | Natural Color | Standard | AiSi, JIS/ASTM/AISI/ASME/DIN/GB |

| Application | Furniture Decoration | ||

| Highlight | 0.3mm Heat Resistant Stainless Steel Sheet,Rustproof Heat Resistant Stainless Steel Sheet,Hot Rolled 8k Stainless Steel Sheet |

||

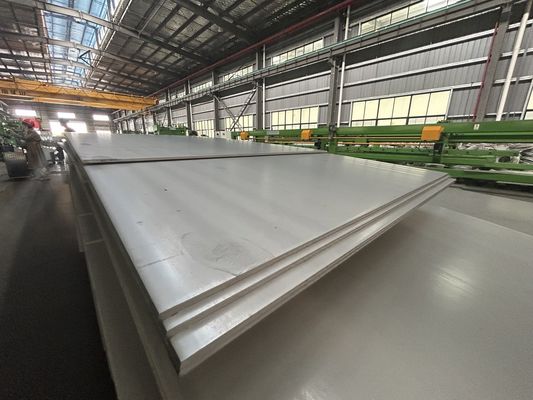

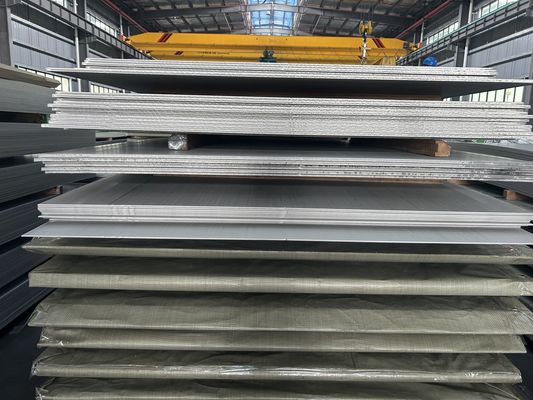

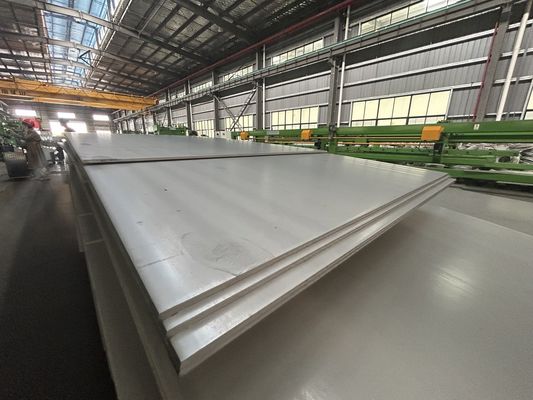

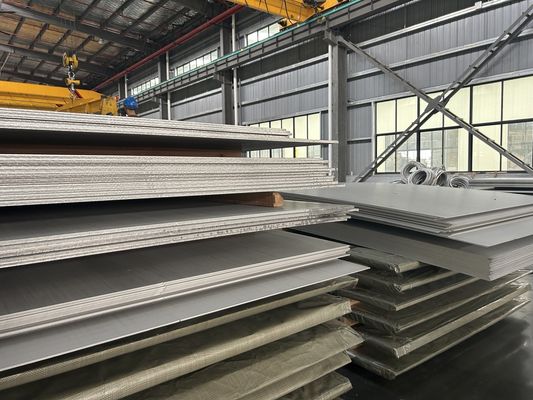

Thickness 0.3mm - 200mm Stainless Steel Sheet

Stainless steel does not stain, corrode, or rust as easily as regular carbon steel and provides high strength and impact resistance along with the aesthetic appeal. The material also has anti-bacterial qualities and is easy to clean and sanitize.

Stainless steel sheet and stainless steel plate are both a perfect solution for applications that require a durable metal with anti-oxidation qualities.

| Product Name | Stainless Steel Sheet |

| Type | Cold / Hot rolled |

| Surface Finish | BA, 2B, 2D, 4K, 6K, 8K, NO.4, HL, SB, Embossed |

| Standard | GB JIS ASTM ASME EN etc |

| Grade | Stainless steel 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 904L / 2205 / 2507 / 32760 / 253MA / 254SMo / XM-19 / S31803 /S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65 etc |

| Monel 400 / Monel K-500 | |

| Inconel 600 / Inconel 601 / Inconel 625 / Inconel 617 / Inconel 690 / Inconel 718 / Inconel X-750 | |

| Incoloy A-286 / Incoloy 800 / Incoloy 800H / Incoloy 800HT | |

| Incoloy 825 / Incoloy 901 / Incoloy 925 / Incoloy 926 | |

| Nimonic 75 / Nimonic 80A / Nimonic 90 / Nimonic 105 / Nimonic C263 / L-605 | |

| Hastelloy B / Hastelloy B-2 / Hastelloy B-3 / Hastelloy C / Hastelloy C-276 / Hastelloy C-22 | |

| Hastelloy C-4 / Hastelloy C-2000 / Hastelloy G-35 / Hastelloy X / Hastelloy N | |

| PH stainless steel 15-5PH / 17-4PH / 17-7PH | |

| Thickness | Cold rolled 0.3mm - 6mm Hot rolled 2.5mm-200mm |

| Width | Cold rolled 10mm - 2000mm Hot rolled 1000mm-3500mm |

| Application | Construction, Chemical, Pharmaceutical & Bio-Medical, Petrochemical & Refinery, Environmental, Food Processing, Aviation, ChemicalFertilizer, Sewage Disposal, Desalination, Waste Incineration etc. |

| Processing Service | Machining : Turning / Milling / Planing / Drilling / Boring / Grinding / Gear Cutting / CNC Machining |

| Deformation processing : Bending / Cutting / Rolling / Stamping | |

| Welded | |

| Forged | |

| Service | OEM, customized processing service, customized fabrication by drawings |

| Export Packing | Waterproof paper, and steel strip packed. |

| Standard Export Seaworthy Package.Suit for all kinds of transport,or as required |

Chemical Component

|

Grade

|

C

|

Si

|

Mn

|

P

|

S

|

Ni

|

Cr

|

Mo

|

|

201

|

≤0.15

|

≤0.75

|

5.5-7.5

|

≤0.06

|

≤0.03

|

3.5-5.5

|

16.0-18.0

|

-

|

|

202

|

≤0.15

|

≤1.0

|

7.5-10.0

|

≤0.06

|

≤0.03

|

4.-6.0

|

17.0-19.0

|

-

|

|

301

|

≤0.15

|

≤1.0

|

≤2.0

|

≤0.045

|

≤0.03

|

6.0-8.0

|

16.0-18.0

|

-

|

|

302

|

≤0.15

|

≤1.0

|

≤2.0

|

≤0.035

|

≤0.03 |

8.0-10.0

|

17.0-19.0

|

-

|

|

304

|

≤0.08

|

≤1.0

|

≤2.0

|

≤0.045

|

≤0.03

|

8.0-10.5

|

18.0-20.0

|

|

|

304L

|

≤0.03

|

≤1.0

|

≤2.0

|

≤0.035

|

≤0.03

|

9.0-13.0

|

18.0-20.0

|

|

|

309S

|

≤0.08

|

≤1.0

|

≤2.0

|

≤0.045

|

≤0.03

|

12.0-15.0

|

22.0-24.0

|

|

|

310S

|

≤0.08

|

≤1.5

|

≤2.0

|

≤0.035

|

≤0.03

|

19.0-22.0

|

24.0-26.0

|

|

|

316

|

≤0.08

|

≤1.0

|

≤2.0

|

≤0.045

|

≤0.03

|

10.0-14.0

|

16.0-18.0

|

2.0-3.0

|

|

316L

|

≤0.03

|

≤1.0

|

≤2.0

|

≤0.045

|

≤0.03

|

12.0-15.0

|

16.0-18.0

|

2.0-3.0

|

|

321

|

≤0.08

|

≤1.0

|

≤2.0

|

≤0.035

|

≤0.03

|

9.0-13.0

|

17.0-19.0

|

-

|

|

904L

|

≤2.0

|

≤0.045

|

≤1.0

|

≤0.035

|

-

|

23.0-28.0

|

19.0-23.0

|

4.0-5.0

|

|

2205

|

≤0.03

|

≤1.0

|

≤2.0

|

≤0.030

|

≤0.02

|

4.5-6.5

|

22.0-23.0

|

3.0-3.5

|

|

2507

|

≤0.03

|

≤0.80

|

≤1.2

|

≤0.035

|

≤0.02

|

6.0-8.0

|

24.0-26.0

|

3.0-5.0

|

|

2520

|

≤0.08

|

≤1.5

|

≤2.0

|

≤0.045

|

≤0.03

|

0.19-0.22

|

0.24-0.26

|

-

|

|

410

|

≤0.15

|

≤1.0

|

≤1.0

|

≤0.035

|

≤0.03

|

-

|

11.5-13.5

|

-

|

|

430

|

0.12

|

≤0.75

|

≤1.0

|

≤0.040

|

≤0.03

|

≤0.60

|

16.0-18.0

|

-

|

Surface Finish

| Itme | Surface finishing | Surface finishing methods | Main application |

| NO. 1 | HR | Heat treatment after hot rolling, pickling, or with treatment | For without the purpose of the surface gloss |

| NO. 2D | Without the SPM | Method of heat treatment after cold rolling, pickling surface roller with wool or eventually a light rolling a matte surface processing | General materials, building materials. |

| NO. 2B | After SPM | Giving No. 2 processing materials appropriate method of cold light sheen | General materials, building materials ( most of the goods are processed ) |

| BA | Bright annealed | Bright heat treatment after cold rolling, in order to be more shiny, cold light effect | Automotive parts, home appliances, vehicles, medical equipment, food equipment |

| NO. 3 | Shiny, coarse grain processing | The NO. 2D or NO. 2B processing timber No. 100-120 polishing abrasive grinding belt | Building materials, kitchen supplies |

| NO. 4 | After CPL | The NO. 2D or NO. 2B processing timber No. 150-180 polishing abrasive grinding belt | Building materials, kitchen supplies, vehicles, medical equipment, food equipment |

| 240# | Grinding of fine lines | The NO. 2D or NO. 2B processing timber 240 polishing abrasive grinding belt | Kitchen appliances |

| 320# | More than 240 lines of grinding | The NO. 2D or NO. 2B processing timber 320 polishing abrasive grinding belt | Kitchen appliances |

| 400# | Close to BA luster | The MO. 2B timber 400 polishing wheel polishing method | Building materials, kitchen utensils |

| HL | Polishing line having a long continuous processing | In a suitable size ( usually mostly No. 150-240 grit ) abrasive tape for as long as the hair, having a continuous processing method of polishing line | The most common building materials processing |

| NO. 6 | NO. 4 processing less than the reflection, the extinction | NO. 4 processing material used for polishing Tampico brushing | Building materials, decorative |

| NO. 7 | Highly accurate reflectance mirror processing | No. 600 of the rotary buff with a polishing | Building materials, decorative |

| NO. 8 | Highest reflectivity mirror finish | Fine particles of abrasive material in order polishing, mirror polishing with a polishing | Building materials, decorative, mirrors |

![]()

![]()

![]()

Surface Finish

![]()

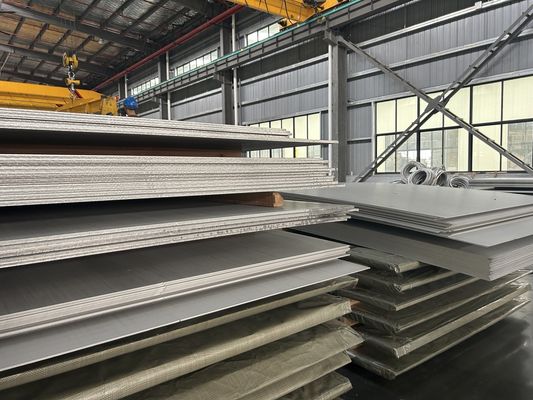

Applications

It is widely used in high temperature applications, medical devices, building materials, chemistry, food industry, agriculture,ship components. It also applies to food, beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs,and screen.

![]()

![]()

![]()

Product Paking

![]()

Delivery

![]()

FAQ

1. How long will it take to execute my order?

Our normal produce time is 7-15 working days.but we have many models in stock.

2. How much will the shipping cost be?

This will depend on the size and weight of your order and the method of shipping.

3. Do you provide samples?

Yes, we can provide samples . We can send the samples by TNT,DHL, FEDEX, EMS, UPS or to your warehouse

4. Do you have products in stock?

There are 600 tons stock for various size .pls kindly inform us what model you need , we will send stock details to you .

5. Can I visit you?

Sure, Pls let us know if you have a plan to visit our company, we will arrange it for you.

6. Q: Are you trading company or manufacturer?

A: We are professional manufacturer for steel ,and our company also is a very professional and technical foreign trade company for steel products. We have more export experience with competitive price and best after-sales service. Apart from this,we can provide a wide range of steel products to meet the requirement of customer.

7. Q: Will you delivery the goods on time?

A: Yes,we promise to provide best quality products and delivery on time no matter if the price change lot or not. Honesty is our company's tenet.

8. Q: How can I get your quotation as soon as possible?

A: The email and fax will be checked within 24 hours,meanwhile,Wechat and WhatsApp will be online in 24 hours. Please send us your requirement and order information,specification(Steel grade,size,quantity,destination port),we will work out a best price soon.

9. Q: Do you have any certifications?

A: Yes,that's what we guarantee to our clients. we have IS09000,IS09001 certificate,APISL PSL-1 CE certificates etc.Our products are of high quality and we have professional engineers and development team.

10. Q: What is your terms of payment?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shipment or paid against copy of B/L within 5 working days. 100% Irrevocable L/C at sight is favorable payment term as well.

11. Q: Do you accept the third party inspection?

A: Yes absolutely we accept.